-

Reolink TrackMix PoE – 4K dual lens surveillance camera review

The Reolink TrackMix PoE is one of the newest and most promising smart 4K surveillance cameras on the market. In my detailed test, I put the camera through its paces to discover its strengths and weaknesses. From the easy installation and impressive image quality to the intelligent tracking options, the Reolink TrackMix PoE offers numerous features that I have tested extensively. Find out in this article how the camera performs in practice and why it could be an excellent choice for monitoring your home.

-

Reolink Argus 4 Pro review: The wireless surveillance camera with 4K and ColorX technology

The Reolink Argus 4 Pro is one of the newest and most advanced surveillance cameras on the market. With its impressive 180° field of view in 4K UHD resolution and innovative ColorX technology, it sets new standards in home and business security. In this blog entry, I will go into detail about the installation and setup of the Reolink Argus 4 Pro surveillance camera, explain its technical specifications and examine the advantages and disadvantages of this camera in a test. I will also point out possible solutions for any disadvantages and provide information on the various sources of supply. This article will help you better understand the Reolink Argus…

-

Build your own garden kitchen – worktop and jamb for the outdoor kitchen

After completing the electrics and water supply in my outdoor garden kitchen, it was now time to install the worktop. I wanted to build the work area of the outdoor kitchen in such a way that I would have individual zones to work in for the barbecue, the bar and also the washbasin area. In this post, I describe in a step-by-step guide how I used OSB boards and Fermacell boards to create a stable and moisture-resistant base for the vinyl tiles. These measures were necessary to make the worktop robust, scratch-resistant and easy to clean, so that it meets the requirements of an outdoor kitchen.

-

Reolink Duo 3 PoE surveillance camera tested against 2 RLC 810A

In my latest smart home project, I replaced my two Reolink RLC-810A cameras with the Reolink Duo 3 PoE surveillance camera with dual lens. I was particularly interested in whether the 180° detection of the Duo 3 PoE could actually improve the monitoring of my driveway and carport. With its 16-megapixel resolution and 2-way communication capability, the Duo 3 PoE promised superior technology and more comprehensive security. But would all the effort and financial investment really be worth it or were the two old camera models better? I would like to explore these questions in this blog post.

-

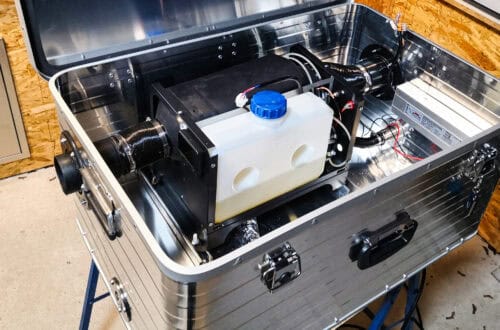

Designing a smart and efficient garden kitchen – installing lights, sockets and water connections

The development of my garden kitchen has made significant progress, particularly in the areas of electrical installation, water installation and the integration of smart technologies for lighting and control. I’d like to give you some insight and practical tips on how I overcame these challenges, from carefully planning the lighting to installing smart sockets and light switches that enable flexible and efficient use.

-

Build your own garden kitchen – solid half-timbered roof with OSB and welded sheeting for the outdoor kitchen

When building my garden kitchen, the next priority was to construct a robust wooden roof to create a sheltered area for the gas barbecue and work surfaces. The roof was to consist of solid wooden beams which I wanted to screw directly onto the walls made of glued aerated concrete blocks. The covering should be made with sheet piling and OSB boards. My plan also included fitting the guttering, the end plates and gluing the welding membrane to make the roof weatherproof. In this entry I will show you step by step how I carried out the individual installations and what I had to pay particular attention to. Of course,…