Building a new pool – dismantling BPC decking and pool technology

Within 2 days I have now also dismantled my old free-standing BPC pool terrace so that I can finally start building the new pool in the garden. The pool terrace was laid in the garden around the pool a few years ago.

Partly the terrace was detached because the pool is on a slope. So in addition to the BPC boards and the WPC overlays, I also had to remove the substructure made of solid larch beams.

As I wanted to reuse the individual components, especially the decking boards and the wooden beams, the dismantling had to be well planned.

I also documented the construction of my BPC pool deck here on the blog.

In the article“Project pool terrace – building the free-standing substructure for the BPC planks” and in the article“Project pool terrace – building the substructure and laying the BPC planks” you can see more details.

Pool remodeling – The pool terrace is rebuilt

As I wrote in the last post, on the deconstruction of the steel wall, our pool is undergoing a major rebuild.

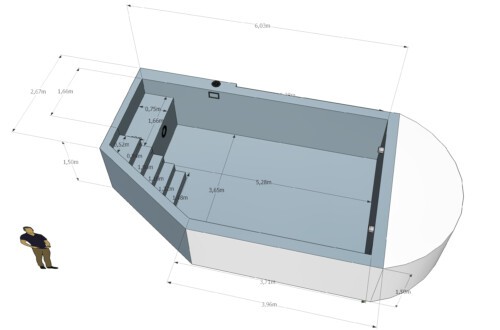

The old oval steel wall pool is to be turned into a masonry pool made of shell stones. The new pool gets a proper staircase and a sunbathing area in the water.

The steel wall pool is surrounded by retaining walls on the long sides. These retaining walls of shuttering blocks will form the new pool exterior walls.

At the curves, I had stabilized the steel wall with a wall cast from concrete. This retaining wall must now be removed because the pool is being enlarged.

Part of the pool terrace is built on and against the eastern retaining wall. Of course, I have to build back the terrace before removing the retaining wall. I have to be careful and cautious because most of the materials can be reused.

WPC and BPC by the pool – what’s the difference?

When I decided to build my pool terrace, I was faced with the choice between WPC and BPC wood for the decking and the terrace substructure. Both materials offer specific advantages and disadvantages, which I weighed up carefully.

WPC

WPC (Wood Plastic Composite) is a mixture of wood fibers and plastic, which gives it a wood-like appearance.

The great advantage of WPC is its good resistance to moisture and mold, which is particularly important near a pool.

However, WPC tends to heat up in strong sunlight, which can be unpleasant on hot summer days.

In addition, the material can expand or contract with temperature fluctuations, which requires careful installation.

BPC

BPC (Bamboo Plastic Composite), on the other hand, consists of bamboo fibers and plastic.

This material is similarly resistant to moisture and mold as WPC, but it is characterized by an even higher density and hardness.

BPC is also less susceptible to thermal expansion and offers greater UV resistance than WPC, making it less susceptible to fading.

One disadvantage, however, is that BPC is often more expensive than WPC and may not be as readily available.

I chose BPC as the decking material for my pool deck because it offered the long-term durability and low maintenance I was looking for.

The investment seemed justified to me, even if the costs were higher, as the longevity of the material compensates for the initial outlay.

Unfortunately, it turned out that my plans didn’t work out. Unfortunately, I was unable to repeat the consistently good experience with my WPC garden terrace with the BPC pool terrace.

- ☀️ LIEFERUMFANG: Komplett-Bausatz bestehend aus WPC Dielen, Unterkonstruktion, Abstandshalter, Schrauben, Dehnschrauben & Dübel aus Edelstahl, Anfang- & Endclips

- ☀️ HOCHWERTIG: Formstabil & robust * Belastbarkeit: 450 kg / m² * Rutschfester WPC-Verbundstoff * UV-beständig * Feuchtigkeitsabweisend * Langlebiger und pflegeleichter als Holz

- ☀️ UNKOMPLIZIERT: Praktisches Klicksystem * inkl. ausführlicher Aufbauanleitung Step-by-Step * Resistenz gegen Pilz- & Insektenbefall * leicht zu reinigen * bis -30°C frostsicher

- ☀️ HINWEIS: die Unterkonstruktion inkl. Schrauben usw. ist nicht in einem gesonderten Karton, sondern in den einzelnen Dielen-Paketen mit eingepackt

- ☀️ GEEIGNET: für Terrassen, Decks und Balkone, Gartenwege, als Pool-Umrandung, zum Verkleiden von Hochbeeten u.v.m.

Removing BPC floorboards

The pool deck was originally going to be extended over my gabions to the plateau of the garden kitchen. But since I still had to do some preparations there, the terrace ended so far directly in front of the gabions.

The first terrace plank was screwed directly into the substructure with stainless steel screws. But all other decking boards I have fixed with a special system.

For this purpose, small staples are inserted between the planks. These clips grip into the groove of the plank and pull the plank down as it is screwed into place.

In this way, 2 planks are always attached to a transition point. A system which I like very much because it is stable and yet invisible.

Using a cordless screwdriver and the appropriate Torx bit, the clamps were opened and the planks were removed one by one.

I labeled the planks and stored them neatly. These are to be reassembled later in the correct order.

Damage to the substructure of the pool terrace

Dismantling the decking boards is relatively time-consuming but not particularly difficult. The screws in the retaining clips between the decking boards were absolutely fine. No rust interfered with the removal.

The substructure, on the other hand, was anything but intact. In my video“Experience report – 3 years BPC | WPC pool terrace in the slope – conclusion” I had already described my experiences after 3 years BPC pool terrace.

However, with the removal of the decking boards, the full extent of the damage to the substructure became apparent.

The substructure consisted of 100 x 100 mm larch wood. I attached 60 x 40 mm counter battens to this beam.

The counter-battening was then doubled up with WPC construction timber. And it is precisely this WPC construction wood that has disappointed me insanely.

The hollow timbers were broken. Small gaps and cracks had formed everywhere – even though the installation had been frost-proof. The screws have come out of the WPC in some places, leaving more holes.

Deconstruction of the substructure – Even more problems

After taking down the WPC construction timbers, I was able to take care of the larch counter-battens and the large beams. But here, too, unexpected problems arose.

The counter-battening was fixed to the large wooden beams with adjusting screws. The adjustment screws are completely countersunk in the counter-battens and can then be precisely aligned by turning the screw up and down.

With these adjustment screws I was able to level the deck.

The screws are well loadable from the top. However, the counter-battening to the side is very unstable. I had additionally fixed the 60×40 mm timbers with rafter purlin anchors.

In this way, the substructure was perfectly aligned in height and extremely stable.

Unfortunately, the adjustment screws were not rust-proof. When unscrewing the screws, I had already destroyed 3 bits after the first 5 screws. I had not experienced that before.

The screws themselves were still completely intact and would have held the deck for many more years.

In the end, I cut the screws with my angle grinder. This was not a perfect solution, but it was always practical.

Zuletzt aktualisiert am 3. March 2026 um 00:23 . Ich weise darauf hin, dass sich hier angezeigte Preise inzwischen geändert haben können. Alle Angaben ohne Gewähr. (*) Bei den verwendeten Produktlinks handelt es sich um Affiliate Links. Ich bin nicht der Verkäufer des Produktes. Als Amazon-Partner verdiene ich an qualifizierten Verkäufen. Dein Preis ändert sich jedoch nicht.

Video: Dismantling my pool terrace in the garden

I will be following the entire conversion of our steel wall pool to a stone pool with my camera. In my playlist for the project pool you can watch the whole process in peace.

I have recorded the dismantling of the WPC/ BPC pool terrace in the video Pool rebuild – dismantling pool terrace | BPC planks | substructure | pool technology.

If you want to see more of me and my projects, feel free to check out my YouTube channel.

Deconstruction of the wooden beams under the pool terrace

Dismantling the 100 x 100 mm wooden beams was then much easier again. The wooden beams were bolted directly to the concrete retaining wall on the one hand and on a load-bearing beam structure on the other.

Among themselves I had connected the beams with angle connectors, perforated plates and large wood screws. This construction was extremely stable and yet, with the right tools, easy to disassemble.

To protect the beams from moisture, the installation was carried out in U-post beams. Thus, a distance of approx. 5 cm to the concrete floor was always ensured. I used small 5 x 5 cm rubber mats as spacers on the wall.

- PAKETINHALT: 5 x Lochplatten ; GRSSE: 200 x 80 mm, DICKE: 2 mm; LCHER: 40 x 5 mm. Schrauben sind nicht im Lieferumfang enthalten.

- QUALITTSMATERIAL: Die verzinkten Lochplatten sind aus hochwertigem 2,0 mm starkem verzinktem Stahlblech gefertigt und ermglichen eine robuste und langlebige Verbindung. Seine Struktur sorgt fr Festigkeit und Korrosionsbestndigkeit und macht es zu einer ausgezeichneten Wahl fr Innen- und Auenanwendungen.

- ROBUST & LANGLEBIG: Das versetzte Lochmuster erhht die Gesamtfestigkeit und Stabilitt der Verbindung. Durch den Versatz der Lcher in jeder Reihe bieten die Platten eine verbesserte Tragfhigkeit und verteilen die Krfte gleichmiger auf die Fuge. Dieses Konstruktionsmerkmal trgt dazu bei, Spannungskonzentrationen zu verhindern und das Risiko von Rissen oder Ausfllen zu minimieren.

- EINFACHE INSTALLATION: Die vorgebohrten Lcher in der Platte ermglichen eine einfache und sichere Befestigung mit Schrauben oder Bolzen.

- VIELSEITIGE ANWENDUNG: Unsere verzinkten Lochplatten eignen sich fr eine Vielzahl von Holzbauanwendungen, wie zum Beispiel den Bau von Mbeln, Regalen, Holzkonstruktionen im Innen- und Auenbereich sowie fr Heimwerkerprojekte.

Conversion pool terrace in the garden – How to proceed?

It took me a good 2 days to remove the pool deck. Now I can take care of removing the concrete retaining wall on the eastern side.

Once this wall is removed, the rebuilding of our pool can begin.

Summary and conclusion

I faced a few challenges when dismantling my pool terrace, which was made from WPC and BPC materials.

I had to dismantle the terrace, originally built around the oval steel wall pool, to be able to start rebuilding the pool.

The steel walls of the pool were supported by reinforced formwork stone walls, which I now wanted to use as the new outer walls of the pool.

The decision between WPC (Wood Plastic Composite) and BPC (Bamboo Plastic Composite) was decisive when planning the construction of the pool terrace at the time, as both materials have specific properties that make them suitable for use near a pool.

WPC offers good resistance to moisture and mold, making it a good choice for pool environments. However, it can expand in strong sunlight and is very warm on hot days.

BPC, on the other hand, made from bamboo fibers and plastic, offers similar advantages to WPC, but with increased density and hardness as well as better temperature stability and UV resistance, which makes it less susceptible to fading.

Despite the higher price, I chose BPC for the decking of my pool terrace because of its durability and low maintenance.

The deconstruction of the terrace required careful planning in order to preserve the materials for reuse.

This included the careful dismantling of the BPC boards and the wooden substructure.

FAQ on dismantling the pool terrace

1. why was the pool terrace removed?

The pool terrace had to be dismantled so that the pool could be rebuilt. The original steel wall pool is to be converted into a brick pool, which made it necessary to remove the terrace and the retaining wall on the east side.

2 What were the challenges in dismantling the terrace?

Some of the difficulties were in dismantling the free-standing structure, especially as the materials were to be reused. In addition, damage occurred to the WPC substructure, which made dismantling more difficult.

3. what is the difference between WPC and BPC for use by the pool?

- WPC (Wood Plastic Composite) consists of wood fibers and plastic and offers resistance to moisture and mold, but can expand and heat up strongly when exposed to high heat.

- BPC (Bamboo Plastic Composite) contains bamboo fibers and plastic and is harder and more UV-resistant than WPC. It is less susceptible to temperature fluctuations, but more expensive.

4 Why was BPC used instead of WPC for the terrace?

BPC was chosen because of its greater durability and lower maintenance requirements. The UV resistance and stability of the material in the event of temperature fluctuations were further advantages that led to the decision in favor of BPC.

5. what problems occurred with the substructure of the terrace?

The substructure, consisting of WPC hollow chamber timbers and larch wood, showed cracks and damage to the WPC elements. Despite frost-proof installation, these were susceptible to breakage and some screws had come loose, which made dismantling difficult.

6. how was the removal of the BPC planks carried out?

The BPC planks were installed with a special invisible fastening system that used staples between the planks. These staples were loosened with a cordless screwdriver, and the planks were labeled and stored so that they could be reused later in the correct order.

7 Why was the dismantling of the adjusting screws problematic?

The adjusting screws, which were used to adjust the height of the substructure, were badly rusted. Several bits broke off during unscrewing, which is why an angle grinder had to be used to cut through the screws.

8. how was the stability of the substructure ensured?

The construction consisted of solid larch beams mounted in U-post supports to ensure a distance from the ground. Angle connectors and perforated plates provided additional stability.

9 What are the next steps after dismantling the terrace?

Once the terrace has been dismantled, the eastern retaining wall will be removed. As soon as this work has been completed, construction of the new stone pool can begin.

10. where can you follow the entire conversion process?

The entire pool conversion is documented on my YouTube channel COMMAIK, including the dismantling of the pool terrace and the planned construction work for the new pool.

- ☀️ LIEFERUMFANG: Komplett-Bausatz bestehend aus WPC Dielen, Unterkonstruktion, Abstandshalter, Schrauben, Dehnschrauben & Dübel aus Edelstahl, Anfang- & Endclips

- ☀️ HOCHWERTIG: Formstabil & robust * Belastbarkeit: 450 kg / m² * Rutschfester WPC-Verbundstoff * UV-beständig * Feuchtigkeitsabweisend * Langlebiger und pflegeleichter als Holz

- ☀️ UNKOMPLIZIERT: Praktisches Klicksystem * inkl. ausführlicher Aufbauanleitung Step-by-Step * Resistenz gegen Pilz- & Insektenbefall * leicht zu reinigen * bis -30°C frostsicher

- ☀️ HINWEIS: die Unterkonstruktion inkl. Schrauben usw. ist nicht in einem gesonderten Karton, sondern in den einzelnen Dielen-Paketen mit eingepackt

- ☀️ GEEIGNET: für Terrassen, Decks und Balkone, Gartenwege, als Pool-Umrandung, zum Verkleiden von Hochbeeten u.v.m.

Dieser Beitrag ist auch verfügbar auf:

English

Deutsch