Efficient heating with infrared heating foil: installation, experience and tips for electric wall heating

An infrared heating foil as wall heating can heat rooms efficiently and sustainably. In my current project, I tested this technology in an old cellar that was previously difficult to heat. From installation and test runs to control with smart systems, I share my experiences, show the advantages and disadvantages of infrared heating and explain how the humidity in the room was reduced.

What you can expect in this blog post

- What is an infrared heating foil?

Explanation of how infrared heating technology works and its advantages. - Technical details of the heating foil

Design, efficiency and operation with low voltage. - Planning and preparation of my project

Initial situation in the cellar, choice of materials and challenges in heating. - Installing the infrared heating foil

Step-by-step instructions for installation and preparation of the wall surfaces. - Results and efficiency test

Measurements for heat development, reduction of wall humidity and power consumption analysis. - Advantages and disadvantages of infrared heating

Personal experiences and assessments of heating performance, integration and flexibility. - Sustainability and smart control

Use of my PV surplus electricity and optimization of the heating via Shelly and Home Assistant. - Video on installing the heating foil

Insight into the complete installation process with tips and test results.

- Infrarot Heizfolie Made in Germany, 4-lagig, 1-fach isoliert, extra robust und langlebig; perforiert und vlieskaschiert, erleichtert die Verarbeitung beim Anbringen, einfache und schnelle Installation

- Die Besonderheit dieser Heizfolie ist die Vlies Laminierung und gleichmäßige Perforierung (Lochung), welches eine einfach Verarbeiten z.B. in Putz oder Fliesenkleber ermöglicht

- Betriebsspannung: 36V | max. Leistungsaufnahme 150Watt/m² +/-10% | Bahnbreite 60cm | aktiver Heizbereich 55cm | Wirkungsgrad ca. 98% | beliebig kürzbar

- Diese wartungsfreie Heizung sorgt für eine homogene Wärmeverteilung mit hoher Energieeffizienz | geringe Aufbauhöhe von 0,4mm | Verminderte Schimmelbildung

- mögliche Einsatzbereiche: Fußbodenheizung, Bodenheizung, Wandheizung, Deckenheizung, Flächenheizung, Elektroheizkörper, Raumheizung, Badheizung

What is an infrared heating foil and how does it work?

Infrared heating foils are modern, energy-efficient panel heaters that convert electrical energy into infrared radiation with virtually no loss. In contrast to conventional radiators, which heat the air in the room, this technology emits heat directly to walls, furniture and other objects in the room. The infrared radiation has a wavelength of 7 to 14 micrometers and produces a pleasant, even heat. This form of radiant heat ensures a healthy indoor climate, as there is no air circulation that could stir up dust.

Technical function of the infrared heating foil

The heating foil consists of carbon-based, electrically conductive fibers that are connected to each other by copper contacts. These fibers are embedded in several layers of insulation and convert electrical energy directly into infrared radiation with an efficiency of up to 98 %.

The active heating surface of the foil is approx. 82 %, which ensures an even temperature distribution on the wall. The maximum temperature resistance of the film is 100 °C, which prevents the walls from overheating.

For operation, the heating foil is usually supplied with a low-voltage voltage of 24V AC/DC via a transformer. A control system, for example via a smart WLAN thermostat or a Shelly switch, ensures automatic control and optimization of the heating cycles.

Comparison: Infrared heating foil vs. infrared heating panels

| Feature | Infrared heating foil | Infrared heating panels |

|---|---|---|

| Mounting | Can be integrated directly into walls, ceilings or floors | Can be mounted on the wall or ceiling |

| Heat distribution | Wide, even heat distribution | Point-directed radiant heat |

| Flexibility | Can be shortened and adapted to different surfaces | Standard sizes with fixed shape |

| Design | Invisible after installation | Visible, often with an aesthetic design |

| Areas of application | Ideal for large-area, invisible applications | Good for living spaces, as additional heating |

Infrared heating foils are particularly suitable for rooms where unobtrusive, large-area heating is required, while infrared heating panels are often used as visual design elements in living spaces. Both technologies are based on the same physical principle of radiant heat, but differ in the type of installation and the distribution of heat.

Sustainability and use of infrared wall heating in combination with my PV system

In my current project, I have integrated the infrared heating foil into the energy supply as a sustainable heating solution. Thanks to my own photovoltaic system, I would like to use surplus solar power efficiently to heat my cellar.

It is controlled via a Shelly system in combination with a WLAN thermostat, which automatically activates the heating as soon as sufficient excess power is available. This form of energy management maximizes self-consumption and minimizes the use of fossil energy sources.

Technically, the heating foil is based on carbon-based, electrically conductive fibers. These convert electrical energy into infrared radiation with an efficiency of up to 98 %. The radiant heat is distributed evenly over approx. 82 % of the active heating surface and heats walls and objects in the room directly.

In combination with a PV system, the heating foil is particularly efficient, as it can cover its electricity requirements directly from renewable energies and thus operate in an almost climate-neutral manner.

This strategy is in line with the requirements of the German Climate Protection Act and the Renewable Energy Sources Act (EEG), which promotes the expansion of renewable energies and the reduction of CO₂ emissions. In future, fossil heating methods are to be replaced by sustainable alternatives.

Heating systems such as the infrared heating foil are considered particularly climate-friendly if they are operated with green electricity. The Shelly system ensures that the heating is only active when the PV system is producing surplus energy.

It is true that the use of surplus electricity reduces the feed-in to the grid and thus the already low feed-in tariff. In the long term, however, this leads to cost-efficient self-utilization of solar power, especially after the depreciation phase of the system.

In the cold season, when the demand for heat increases, the automatic adjustment to solar production ensures additional efficiency. This solution supports my goal of reducing heating costs, minimizing CO₂ emissions and meeting legal climate protection requirements.

- Pro Heizfolie Bahn benötigt ein elektrische Fußbodenheizung Anschluss-Set fürs Abdichten von Kabeln und Leitungszwickeln

- Set besteht aus: 2,5m Anschlussleitung Braun, 2,5m Anschlussleitung Blau, 2 Quetschverbinder, 30cm Vulkanisierband / Dichtungsband

- Abdichtband Isolierband ist selbstverschweißend und korrosionsbeständig; schutzt vor Staub, Feuchtigkeit und Korrosion

- Quetsch-Verbinder für eine sichere Verbindung bei Installation von Infrarot Heizfolie; optimale Leitfähigkeit; große Kontaktfläche

- Für eine feste und sichere Verbindung empfehlen wir Ihnen unsere Mi-Heat Crimpzange zu verwenden

Initial situation and project planning

My project started in the basement of an old house from 1900. The room is characterized by thick brick walls, which provide a certain amount of insulation, but also promote moisture problems due to the lack of a concrete foundation. A few years ago, the cellar was extensively renovated and converted into a spa with sauna. The room was given a new concrete floor and the walls were re-plastered on the inside. Unfortunately, however, I had neglected to install underfloor heating at the time.

An important part of the renovation was the draining of the house, during which drainage and water pipes were laid around the foundations. Details on this step can be found in my blog article “Draining the house – installing drainage and water pipes”.

I also protected the cellar walls from rising damp by installing a new horizontal barrier. You can also find more information on this and a conclusion after nine months in the article “Drying out the basement with a new horizontal barrier” as well as instructions for retrofitting a horizontal barrier yourself.

Despite these measures, the average room temperature in winter remained at around 10 °C. It was too cold and unacceptable for the planned use as a spa area. Due to the structural conditions, it was not possible to connect the cellar to the house’s central, water-based heating system.

- 【Einzigartige Intelligente Szenerieerkennung】Das E01 integriert HIKMICROs proprietäre Superszene-Technologie für intelligente, automatische Szenenerkennung. Durch den Einsatz von Deep Learning erkennt es Wasserlecks und Isolationsfehler schnell — wodurch thermische Inspektionen schneller, einfacher und genauer werden. Jetzt aufrüsten: Laden Sie die neueste Firmware von der HIKMICRO-Website herunter, um den Unterschied zu erleben.

- 【Benutzerfreundliches 3-in-1-Werkzeug】 Das E01 vereint Thermometer, Wärmebildkamera und Laserpointer — so bleiben Ihre Temperaturmessgewohnheiten erhalten, während Sie live Wärmebildaufnahmen machen. Einfache Tastensteuerung: Ein-/Ausschalten, Menü, Aufnahme, Videoaufnahme und Farbpalette wechseln — alles in einem intuitiven Layout. Lieferumfang: Bedienungsanleitung, Handgelenkband und 2-in-1-USB-C-Kabel — bereit für sofortige Infrarot-Haussanierungen.

- 【Live-Verbesserte Wärmebildauflösung】 Die IR-Auflösung des Sensors beträgt 96×96, angetrieben von HIKMICROs SuperIR-Bildverbesserungstechnologie. Die HIKMICRO E01 Infrarotkamera erhöht die Wärmebildauflösung in Echtzeit von 96×96 (9.216 Pixel) auf 240×240 (57.600 Pixel) beim Betrachten in Live-Ansicht und beim Aufnehmen von Fotos.

- 【Sofortige Anomalieerkennung】 Die E01 Wärmebildkamera bietet ein Sichtfeld von 50° für die Erfassung großer Flächen. Sie erkennt automatisch Hot Spots (elektrische Fehler), Cold Spots (Feuchtigkeitslecks) und Mittelpunkte — ganz ohne Rätselraten. Stellen Sie benutzerdefinierte Alarmhöhen/-tiefen ein oder passen Sie manuell Niveau und Spanne an, um Anomalien in kritischen Temperaturbereichen genau zu lokalisieren.

- 【Präzision, der Sie vertrauen können】 Die E01 IR-Kamera bietet eine Genauigkeit von ±2°C im weiten Bereich von -20°C bis 400°C — ideal für präzise Hausinspektionen. Passen Sie Abstand und Emissionsgrad an, um Materialien wie Beton, Ziegel oder Metall zu entsprechen, und gewährleisten Sie zuverlässige Messwerte auf jeder Oberfläche.

- 【Benutzerfreundlichkeit】 Der Laserpointer hilft Ihnen, Objekte auch bei Dunkelheit oder in engen Räumen schnell zu fokussieren. Fünf Farbpaletten ermöglichen die Anpassung an jede Szene, egal ob bei der Inspektion elektrischer Anlagen oder der Feuchtigkeitsdetektion. Die HIKMICRO ANALYZER PC-Software erlaubt die Analyse, Überwachung oder Erstellung von 3D-Diagrammen. Ein Stativhalter ist im Lieferumfang enthalten, sodass Sie es für ruhige, freihändige Scans fixieren können.

- 【Robust gebaut, langlebig】 Wiederaufladbarer Akku hält 11 Stunden ununterbrochen. 4 GB Speicherplatz fasst über 30.000 Bilder und 14 Stunden Video. Übersteht Stürze aus 2 Metern Höhe und ist mit der IP54-Bewertung staub- und wasserresistent.

- 【Problemloser Garantie Service】 3 Jahre für das gesamte Gerät / 10 Jahre für den Sensor. Lebenslange Firmware-Updates und technischer Support, sowie lokaler Neukalibrierungsservice sorgen für sorgenfreies Nutzen nach dem Kauf.

Pleasant warmth through infrared radiation

Based on my previous experience with heating systems and the challenges mentioned above, I decided to install an infrared heating foil. This technique seemed ideal, as it allows heat to be emitted evenly over the entire wall surface. It can also be integrated inconspicuously and generates radiant heat that warms walls and objects directly – an important advantage, especially in a room with high humidity.

1. decision for the infrared heating foil

I had previously tried spot heating methods such as an infrared carbon heater, heating mats and an infrared fan heater. However, both systems delivered only limited results.

The radiant heater only warmed certain zones in the room, while the air temperature barely rose. The fan heater did provide heat for a short time, but in addition to the fan noise, it caused an unpleasant draught and was not energy efficient.

In comparison, the infrared heating foil offers an area-wide and even heat distribution of 150W per square meter or linear meter, which also continuously heats larger areas.

2. choice of materials

As this is a damp room, I decided to use a cement-based filler. This is resistant to moisture and reduces the risk of mold growth. The foil was embedded in the filler and smoothed to ensure even heat conduction.

3. power supply and control

The heating foil is powered by a 24 V transformer with an output of 600 watts. The system is smartly controlled by a Shelly switch and a WLAN thermostat. The automation makes it possible to activate the heating as required, especially when my PV system is generating surplus electricity.

With this planning, I was able to ensure that the basement is heated efficiently and sustainably and that a pleasant indoor climate is created for use as a spa area.

- 5,0m Mi-Heat HighEnd Heizfolie der Superlative | 150W/m² für gleichmäßige Oberflächentemperatur und eine schnelle Aufwärm-Geschwindigkeit

- Heizfolie auf Carbon Nanotube Basis. Diese Technologie ermöglicht einen zusätzlichen Effizienzgewinn und erhöht zudem die Betriebssicherheit sowie Belastbarkeit

- Mehrschicht-Isolierung: äußerst robuster und extrem strapazierfähig | Heizfilm bestehend aus 7 Schichten und 5 Hauptkomponenten / sorgfältig ausgewählte Rohstoffe | hochwertige Laminierung

- Mehr Heizfläche: aktive Heizfläche von 96% | vollständig ausgenutzte Folien-Fläche | vergleichsweise schmaler Folien-Randbereichs | maximale Effizienz

- elektrische Wand- oder Deckenheizung mit geringer Aufbauhöhe von nur 0,6mm | das vollflächiges Heizelement ermöglicht das Kürzen der Bahnen an jeder beliebigen Stelle | Temperaturbeständig bis 100°C

Preparation for installing the infrared heating foil

Extensive preparations were required for the installation of the heating foil. The cellar walls were sealed with sealing tape to prevent rising damp from diffusing. This layer was removed cleanly and formed a sufficiently smooth substrate so that additional filling was not necessary.

A stable, even substrate is crucial for the adhesion and even heat distribution of the heating foil.

Test run of the heating foil and first temperature measurements

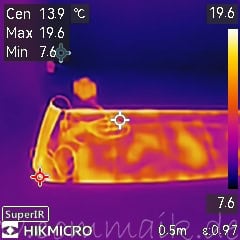

Before installing the heating foil, I first rolled it out on the floor and connected it to the transformer to check its function. The film developed noticeable heat after just a few minutes.

However, temperature differences occurred within the heating surface. Some areas became warmer than others. This was due to the fact that the film was not in direct contact with the cold tiled floor in certain places and therefore worked less efficiently locally.

I bought a thermal imaging camera to record the temperature distribution in detail. This camera visualizes the infrared radiation emitted by surfaces and makes it possible to precisely detect and measure temperature differences.

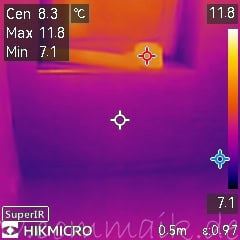

I used the camera to take various measurements in the room before installation. The outside temperature at this time was between -5°C and -7°C.

In the unheated areas, especially in the corners, the temperature was only 6 °C. At 11 °C, the window frames were significantly warmer than the surrounding walls, which were around 8 °C. These measurements confirmed the need to bring large areas of uniform radiant heat into the room in order to reduce temperature differences and cold zones.

After connecting the heating foil, the temperature on the contact surfaces rose to up to 21 °C, while adjacent unheated areas remained at 8 to 10 °C. The measurements clearly showed that complete and bubble-free installation of the foil is crucial for even heat distribution.

Temperature control with integrated sensor

I use a WLAN thermostat with an integrated temperature sensor to control the heating foil. I have dispensed with an external sensor, as the room temperature is reliably recorded even without additional sensors.

The temperature can be regulated automatically via the smart control system and adjusted to the current demand, which is particularly advantageous for using the surplus solar power from my PV system.

Important instructions for the professional installation of infrared heating foils

- Substrate preparation

- The substrate must be even, clean and dry. Any unevenness or cracks must be removed before installation.

- Alternatively, as in my case, a sealing layer can be used as a smooth substrate.

- Cutting the heating foil to size

- The heating foil can be shortened to the desired length, but only on the uncontacted side. Copper contacts and fibers must not be damaged.

- Positioning and laying

- The film must not be laid over expansion joints. Flexible adhesives are recommended for smaller joint movements.

- Overlapping of several sheets is not permitted.

- Electrical connections

- The connection is made via a transformer with low voltage (24 V). Professional installation by a qualified specialist is recommended.

- Temperature monitoring and control

- An integrated temperature sensor in the thermostat records the room temperature and enables automatic control.

- Smart control (e.g. via Shelly) ensures efficient heating cycles, especially when using surplus PV electricity.

- Functional test before completion

- After cutting to size and connection, a functional test is carried out to check the uniform heat development and functionality of the contacts.

- Bonding and protective layer

- The foil is fixed in place with filler and the surface is smoothed to ensure optimum heat distribution and generate pleasant warmth. After drying, the surface can be sanded or painted if required.

Efficient placement and professional installation of the infrared heating foil

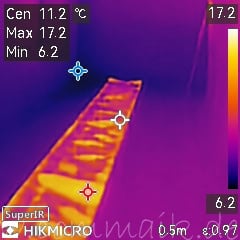

The placement of the infrared heating foil plays a key role in ensuring even and effective heat distribution in the room. The heating foil has a height of 60 cm and was deliberately chosen so that it fits exactly under the windows. The length of 5 meters was also ideal for covering the entire wall surface without interruption and for heating cold zones on the outer wall in a targeted manner.

Installing the heating foil in the wall

For the installation, I first prepared the cement-based filler together with my father. The filler was applied evenly to the wall with a notched trowel.

The infrared heating foil was then pressed directly into the fresh filler and carefully smoothed out with a trowel. We made sure that the foil lay flat on the wall to ensure optimum heat transfer.

The connection cables for the heating foil were fed through two prepared holes behind the installation wall and later connected to the transformer. In the area of the double socket, the foil was cut out cleanly with a cutter to keep the socket accessible.

Finally, the remaining filler was applied thinly to the heating foil and smoothed after drying. The result is an even and smooth surface that is ready for further processing steps.

- Für Schichtdicken bis 10 mm

- Hervorragende Verarbeitungseigenschaften

- Spannungsarm und rissefrei

- Für Spachtelarbeiten gemäß Qualitätsstufen Q1-Q4

- Materialbedarf: ca. 0.80 kg m²/mm

- Verarbeitungszeit bei +20°C: ca. 45 min

- Anstrich- und Klebearbeiten: nach ca. 1 Tag

- Anmischverhältnis: ca. 12,5 l Wasser: 25 kg ARDEX R1

- pH-Wert: ca. 10

- Kugeldruckhärte

Heating control and monitoring

The entire electrical installation was carefully planned for the power supply and control of the infrared heating foil. I laid a 3×1.5 mm² cable from the fuse box to the thermostat and connected it there. However, the output of the thermostat was not connected directly to the transformer.

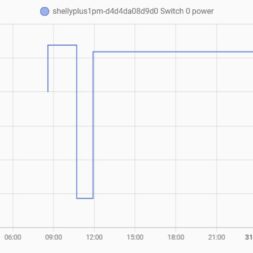

Instead, I connected a Shelly PM1 in between. This allows me to measure the power consumption of the heating in real time and flexibly design the control system. The Shelly also makes it possible to control the heating smartly independently of the thermostat.

A key advantage of this solution is the ability to make optimum use of the surplus solar power from my PV system at a later date. The Shelly system can be used to configure the heating system so that it is preferentially activated when the PV system is producing surplus energy, which can then be used directly for the heating system.

This increases self-consumption and minimizes heating costs in the long term.

Technical components at a glance

1. WLAN thermostat (Tuya control)

The thermostat offers precise control of the room temperature and supports integration into smart home systems. It is compatible with the Tuya app and can be controlled via WLAN and Bluetooth.

- Switching capacity: Up to 3680 W / 16 A

- Temperature sensor: Internal, additional optional external sensor possible

- Compatibility: App control via Tuya Smart or Smart Life

The app can be used to create heating times, temperature profiles and automations, ensuring demand-based and energy-efficient use.

- Unterputz Regler mit Wlan und Bluetooth | per Tuya Smart oder Smart Life App steuerbar | Sprachsteuerung mit Alexa Echo und Google Assistent

- Ideal geeignet zur Steuerung von elektrischen Heizfolien, Dünnbettheizmatten und anderen elektro Heizsystemen | inkl. externen Temperatursensor/Bodensensor/Bodenfühler

- Auch geeignet zur Steuerung von NC-Stellantrieben/Ventilen | HINWEIS: nicht geeignet für NO-Stellantrieben/Ventilen

- Komfort-Funktionen: individuelle Wochenprogrammierung | zeitlich steuerbare Displayhelligkeit z.B. zur Abschaltung des Displays in Schlafräumen

- Max. Schaltleistung 16A / 3680 Watt | programmierbar bodenheizung fussbodenheizung wasserheizung wireless

2. Shelly 1PM (Smart Switch with consumption measurement)

The Shelly 1PM is a WLAN-enabled switching module that both controls the power supply and monitors energy consumption.

- Maximum switching load: 3.5 kW (16 A)

- Consumption measurement: real-time measurement of current and power

- Control: Integration into smart home platforms such as Home Assistant and Tuya

- Smart automation: Control by time, temperature or excess current possible

The Shelly can be flexibly integrated into automation systems and enables heating to be controlled based on excess solar power and other conditions.

3. transformer (24 V / 600 W)

The transformer reduces the mains voltage from 230 V to the low-voltage voltage of 24 V required for the heating foil.

- Output power: 600 watts / 24 V AC

- Design: Safety transformer with protection class IP20

- Mounting: wall or horizontal mounting

The transformer reliably supplies the heating foil with the required voltage and ensures a safe and stable power supply.

Integration and control via app

All components are integrated into my smart home system and are controlled via Home Assistant and the Tuya app. The thermostat regulates the room temperature and can automatically adjust heating times if necessary.

The Shelly PM1 supplements the control system by providing consumption data and enabling automated switching operations.

I have the option of configuring comprehensive automations via Home Assistant. For example, the heating can be switched on automatically when there is a surplus of solar power, while other appliances are prioritized when the power supply is low.

This smart control system ensures efficient heating operation and optimum use of my PV system.

- Geeignet für Plattenstärke 7-40 mm

- Flexibler Tunnel erleichtert die Montage und bietet extra Platz bei der Installation z.B. für Leitungsreserven oder zum Unterbringen von Funkaktoren

- Norm-Kombinationsabstand bei senkrechten & waagerechten Kombinationen

- Kombinationen können durch den Tunnelstutzen vollisoliert verbunden werden

- Lieferumfang: 1 Stück

Video: Efficient heating with infrared heating foil? Installation and power consumption check

In my informative video, I show the entire process for installing the infrared heating foil, from the test run on the floor to filling in the wall. I demonstrate how to check the temperature development and give helpful tips on preparation, installation and wiring.

You can find more projects on the subject of energy-efficient heating and sustainable modernization in my YouTube playlist Basement expansion & renovation and in my blog category Smart Home.

If you want to see more of me and my projects, feel free to check out my YouTube channel.

Zuletzt aktualisiert am 26. November 2025 um 21:59 . Ich weise darauf hin, dass sich hier angezeigte Preise inzwischen geändert haben können. Alle Angaben ohne Gewähr. (*) Bei den verwendeten Produktlinks handelt es sich um Affiliate Links. Ich bin nicht der Verkäufer des Produktes. Als Amazon-Partner verdiene ich an qualifizierten Verkäufen. Dein Preis ändert sich jedoch nicht.

Efficiency test and results

After commissioning the infrared heating foil, I regularly checked the temperature development, the wall humidity and the power consumption. The measurements showed that although the heating system emits heat effectively, the heating of the entire room is delayed by the structural conditions such as thick brick walls.

1. heat development

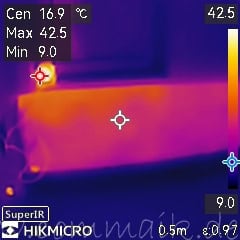

The initial room temperature was around 10 °C. Shortly after switching on the heating foil, the radiant heat was clearly noticeable in the immediate vicinity of the wall. Measurements with the thermal imaging camera showed that the temperature of the heated wall areas rose to up to 22 °C. The ambient temperature in the room, on the other hand, rose only slowly and reached a range of 13 to 14 °C after a few days.

The reasons for the slow heating of the room are the high heat storage capacity of the solid brick walls and the fact that infrared radiation primarily heats objects and not the room air. The relatively low heat output of 450 watts also plays a role here. A larger proportion of the heat energy is absorbed by the wall surfaces and not transferred directly into the air.

2. wall moisture

A central aim of the project was to reduce the moisture in the cellar walls. Before the heating foil was installed, the measured humidity at various points was between 51 and 70 diggit. Significant improvements were observed after two days of heating operation. The moisture values fell by an average of around 10 digits, and in some places by as much as 20 digits.

In particularly humid areas such as the corners of the room, the value was reduced from 70 Diggit to 44 Diggit. This effect is due to the continuous heating of the wall by the infrared radiation. The heat promotes the evaporation of moisture, which is dissipated via the room air. In the long term, this contributes to a healthier indoor climate and a reduction in the risk of mold.

3. power consumption

The power consumption of the heating foil was monitored in real time via the Shelly system. The power output was constantly between 440 and 460 watts and therefore met the technical specifications of the film. Consumption was stable during the operating times and fluctuated only minimally.

Thanks to the smart control system, the operation of the heating could be efficiently adjusted to specific time windows and temperature requirements. This helps to optimize energy use, especially if the heating is operated in conjunction with my PV system. Real-time monitoring also enables the operating costs to be determined precisely and adapted to the current availability of solar power.

The measurements have shown that the infrared heating foil is an effective solution for spot heating and moisture reduction, but has certain limitations when it comes to heating the room air. Control via smart systems plays a decisive role in sustainable and energy-efficient use.

- Zerstörungsfreie Tiefenmessung bis 40 mm-Das RDINSCOS Feuchtigkeitsmessgerät wand misst ohne Nadeln bis 40 mm tief – ideal für Wände, Böden oder Decken, besonders in Keller, Estrich und Mauerwerk

- Frühzeitige Erkennung von Feuchteschäden – Das Baufeuchtemessgerät erkennt verborgene Feuchtigkeit zuverlässig und trägt dazu bei, strukturelle Schäden und unnötige Reparaturen zu vermeiden.

- Kugelsensor für schwer zugängliche Bereiche-Die runde Sonde ermöglicht präzise Messungen in Ecken, Fugen und Kanten. Perfekt für gipskarton, cm messgerät estrich.

- Breite Anwendung in Haus & Wohnbereich – Das elektronische Wandfeuchtemessgerät prüft schnell Feuchtigkeit in Wand, Boden oder Decke. Nicht für Metall geeignet.

- Klares Display & integrierte LED-Taschenlampe – Mit beleuchtetem Farbdisplay, Hold-Funktion, einfacher Kalibrierung und LED-Licht für dunkle Räume – ein ideales Werkzeug für zu Hause.

- Der Feuchtigkeitssensor eignet sich für Heimwerker, Hausbesitzer und Profis – misst die relative Feuchtigkeit und ermöglicht durch Vergleich der Werte die Einschätzung feuchter Bereiche.

Advantages and disadvantages of infrared heating

Infrared heaters offer both clear advantages and some limitations, which vary in importance depending on the usage scenario and structural conditions. Based on my own experience, I will show below how the technique has proven itself in practice.

Advantages of infrared heating

1. high energy efficiency through direct conversion of electricity into heat

The heating foil converts electricity into radiant heat with an efficiency of up to 98 % with virtually no losses. As the heat is transferred directly to objects and walls, hardly any energy is lost through air circulation. In my basement project, this was demonstrated by the fact that the heated wall surfaces quickly became noticeably warm and the radiant heat was effectively transferred to the room.

2. reduction of wall moisture and mold prevention

An important advantage of infrared radiation is the continuous heating of the wall surfaces. This promotes the evaporation of moisture and helps to prevent mold growth in the long term. In my case, the moisture in the cellar walls was significantly reduced within a few days. The effect was particularly visible in the previously heavily used corners, where the humidity values dropped by up to 20 digits after heating.

3. easy integration into existing rooms

The heating foil was easy to install underneath the window surface. After installation and filling, the film is invisible and does not impair the use of the room. This invisible integration is a major advantage over conventional radiators, which often take up space and restrict the room design.

Disadvantages of infrared heating

1. limited heating capacity for large rooms

With a heating output of 450 watts, the foil in my project is not enough to quickly bring the entire basement room of 20 square meters to a comfortable temperature. The radiant heat mainly heats the wall and surrounding objects, while the air temperature rises only slowly. Additional heating elements or a higher heat output would be required for larger rooms.

2. restrictions on placement

In order for the radiant heat to be effectively emitted into the room, the heated wall surfaces must remain permanently free of furniture, large cupboards or wall decorations. In my case, this is not a major problem, as the film was deliberately fitted below the windows. Nevertheless, this restriction is a planning factor that must be taken into account depending on the use and furnishing of a room.

3. no rapid build-up of air heat

The heat is primarily transferred to walls and objects via radiation, which means that the room air temperature increases more slowly than with conventional convection heating systems. This can be disadvantageous in rooms that need to be heated up quickly. In my basement project, longer heating times are therefore required to bring the entire room up to a comfortable temperature.

These objective advantages and disadvantages show that infrared heating is particularly effective in well-insulated rooms or for targeted applications to reduce humidity. For larger areas or rooms with high heat losses, however, an additional or supportive heating solution should be planned.

- Vielseitige Anwendung: Mit 3 Heizstufen und Timer bietet der Veito Blade S Komfort und Wrme.

- Schnelle Aufheizung: Ob auf Terasse, auf Balkon oder Gewchshaus berall einsetzbar.

- Sicher und leise: Mit Umkippschutz, berhitzungsschutz und geruscharmer Betrieb.

- Flexible Montage: Wand, Decke oder mobil mit Stativ (separat erhltlich).

- Energieeffizienz und Langlebigkeit: Maximale Energiegewinnung, hochwertige Konstruktion.

Summary: Efficient heating with infrared heating foil

In my latest project, I installed an infrared heating foil to heat my basement sustainably and energy-efficiently. The infrared technology generates radiant heat, which heats objects and walls directly and thus ensures a pleasant room climate.

The heating foil was installed underneath the windows and was implemented through precise preparation of the substrate and careful installation with cement-based filler. The technology proved to be ideal for uniform wall heating across the entire surface. With smart control via a WLAN thermostat and a Shelly switch, heating operation is efficiently monitored and adjusted to my solar power surplus.

Measurements showed that the wall temperatures rose to up to 22 °C, while the room air temperature increased to 13 to 14 °C after a few days. In addition, the wall humidity was reduced by up to 20 diggit, which reduced the risk of mold growth.

Infrared heating offers clear advantages such as high energy efficiency, moisture reduction and invisible integration. At the same time, there are limitations in terms of heating output in larger rooms and the need for free wall surfaces. However, for well-insulated or special rooms such as my basement SPA area, this technology is a convincing solution.

- Vergessen Sie kalte Böden - unsere innovativen 100 cm breiten Termofol 80W-Fußbodenheizungsfolien sind die Lösung, die Ihnen jeden Tag unglaublichen Komfort bietet. Dank der gleichmäßigen Wärmeverteilung über die gesamte Bodenfläche spüren Sie eine angenehme Wärme unter Ihren Füßen, die Sie an kalten Tagen einhüllt. Heizfolien sind nicht nur äußerst effektiv, sondern auch energieeffizient. Genießen Sie die Wärme und senken Sie gleichzeitig Ihre Heizkosten. Gönnen Sie sich ein wenig Luxus

- Gesundheitliche Vorteile - Dank der Anionen und der Infrarotstrahlung reduzieren wir die Verbreitung von Bakterien und unangenehmen Gerüchen. Darüber hinaus trocknet das System die Bindehaut und die Atemwege nicht aus, was der Gesundheit zugute kommt. Die Fußbodenheizung minimiert die Staubaufwirbelung, was Allergikern und der allgemeinen Luftqualität im Raum zugute kommt

- Vielseitig einsetzbar - Unser komplettes Heizfolienset ist die perfekte Lösung für Laminatböden, Vinyl, Schichtdielen und unter Gipskartonplatten, was es zu einer vielseitigen Lösung macht (mit Ausnahme von Räumen mit höherer Luftfeuchtigkeit wie Bädern). Die Temperatur wird über einen Thermostat eingestellt Bitte beachten Sie, dass die elektrische Fußbodenheizung nicht für die Verwendung unter Teppichböden und Flissen geeignet ist.

- Thermostat H1 - Fortschrittlicher, programmierbarer Thermostat für die perfekte Steuerung Ihrer Heizung! Die Steuerung per Berührungstaste und die 7-Tage-Temperaturprogrammierung sorgen für maximalen Komfort. Schlankes Design mit einer Dicke von nur 27 mm und einem modernen Look. Großes LED-Display und Funktionen wie offenes Fenster und Urlaubsmodus. Das Set verfügt über 2 Lufttemperatursensoren und einen NTC-Temperatursensor für noch höhere Präzision. Temperaturbereich 1-70°C.

- Extrem einfach zu installieren - Das Set besteht aus einer Heizfolie, einem Thermostat und dem gesamten für die Installation erforderlichen Zubehör. Ohne lästige Renovierungsarbeiten können Sie schnell und einfach angenehme Wärme in Ihrem Zuhause genießen. Unsere einfache und übersichtliche Anleitung führt Sie Schritt für Schritt und ein auf YouTube verfügbares Anleitungsvideo durch die gesamte Installationsphase. Wir empfehlen die Verwendung von TERMOFOL Dämmunterlagen unter der Heizfolie

FAQ on infrared heating foil

1. what is an infrared heating foil and how does it work?

Infrared heating foils are flat, electrically operated heaters that convert energy into infrared radiation with virtually no loss. This radiation heats walls, objects and furniture directly without heating the air.

2 What are the advantages of an infrared heating foil?

The film ensures even heat distribution, reduces wall moisture and minimizes mould formation. It works efficiently and can be integrated unobtrusively into walls.

3. how does an infrared heating foil differ from infrared heating panels?

Heating foils are integrated directly into walls, ceilings or floors and distribute the heat over a wide area. Heating panels are visible and emit point-directed radiant heat.

4 How is an infrared heating foil controlled?

It is controlled via a smart thermostat or a Shelly system that automatically regulates the heating based on the temperature and excess electricity from photovoltaic systems.

5. what is the efficiency of the infrared heating foil?

The heating foil has an efficiency of up to 98 % and converts almost all of the electrical energy directly into infrared heat.

6. can an infrared heating foil contribute to moisture reduction?

Yes, the continuous heating of the wall surfaces promotes the evaporation of moisture, which significantly reduces the risk of mold growth.

7 Which materials are suitable for installation in damp rooms?

Cement-based levelling compounds are recommended in damp rooms as they offer moisture resistance and minimize the risk of mould.

8. what is the recommended operating voltage for the heating foil?

The film is operated with a low voltage of 24 V, which is supplied by a transformer.

9. what preparations are necessary for the installation?

The substrate must be even, clean and dry. Unevenness and cracks should be repaired before installing the film.

10. what are the restrictions on the use of an infrared heating foil?

The heat output is limited for large rooms and heated areas must remain free of furniture to ensure effective heat dissipation.

- Hohe Effizienz: Diese Infrarotheizung ist mit einem Karbon-Heizstab ausgerüstet und verfügt über eine Leistung von 1800 Watt. Ein breiter Reflektor sorgt für hohe Ab- und Streustrahlung.

- Vielseitig Einsetzbar: Der Infrarotheizstrahler eignet sich ideal für eine schnelle Aufstellung im gewünschten Wohnbereich, der Garage, im Garten, der Terrasse oder dem Balkon.

- Höchste Sicherheit: Der elektroheizstrahlerhat einen Überhitzungsschutz. Das Gerät ist geräuschlos, dabei geruchslos und für Allergiker geeignet.

- 100% nicht bendend: Der Heizlüfter hat keine Aufheizphase und die wohlige Wärme setzt binnen Sekunden ein. Der Carbon Heizstab leuchtet im warmen Orange (LOW-GLARE), direkter Blick möglich.

- Mehrere Heizstufen: Der Heizstrahler kann mit der Fernbedienung aus der ferne oder per Knopfdruck am Gerät zwischen 4 Heizstufen (ca. 950W-1250W-1500W-1800W) geregelt werden.

Dieser Beitrag ist auch verfügbar auf:

English

Deutsch